Dedication Redefined

Results Amplified

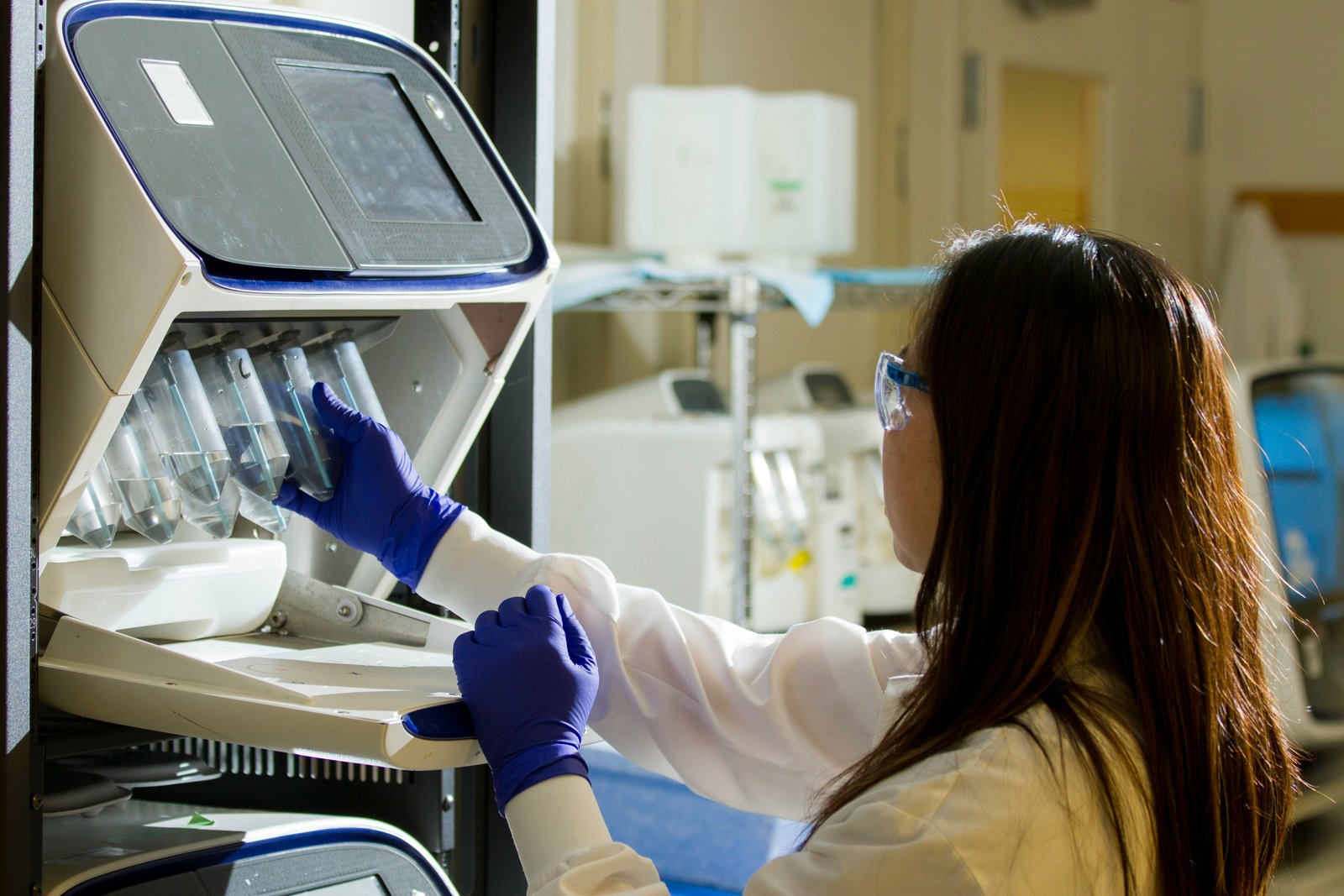

Nexus | Metrology was founded on over 15 years of hands-on experience leading calibration and asset management programs within regulated life science environments. We bring executive-level metrology leadership to pharmaceutical, biotech, medical device, and advanced manufacturing organizations that demand precision, compliance, and operational excellence.

We're dedicated to making a difference in the manufacture of life-changing medicines. Our comprehensive approach integrates precision calibration, cutting-edge metrology science, and on-site support for commissioning, qualification, and validation processes.

With a commitment to excellence and innovation, we empower our clients to bring groundbreaking medications to market efficiently and responsibly.

Contact Our Team15+

Years of GMP Experience

100%

Inspection Ready

35,000+

Instruments Calibrated

0

Calibration Findings